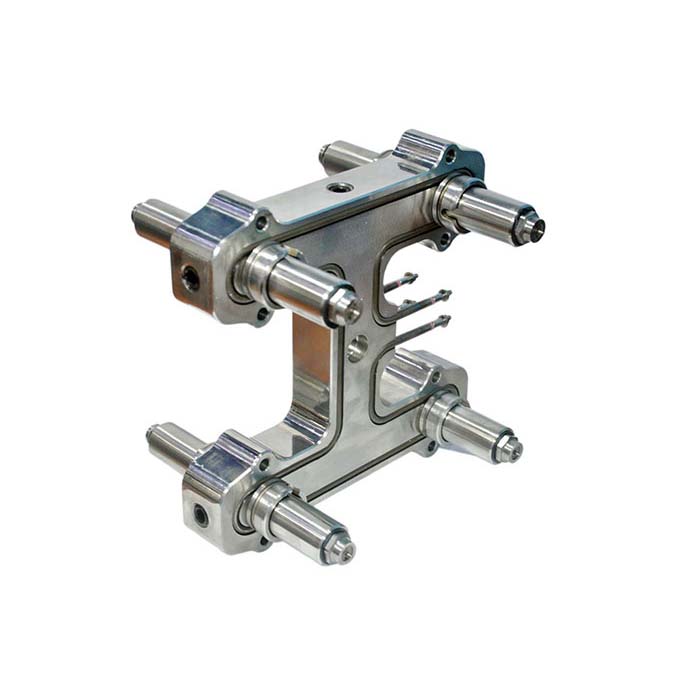

Hot Runner

STACK MOLDING HOT RUNNER

Doubled molding output compare to conventional single face mold, Stack Molds can double the output of and injection machine by distributing the melt plastic into two or more separate mold parting surface, Double output to achieve the high production target.

Advantage of stack Hot runner Mould:instead of increasing the mold size by adding more cavities, a stack, old maintain mold size and machine size by add in second layer of cavities parallel to the first layer. Filling, pack and cooling time will remain same, and only mold open and closing time will add to the cycle time.

Reduce the Part Price:The part price is determined by the machine hour rate, which is directly related to the machine tonnage. A Stack mold requires only about half the clamp tonnage than a single face mold with the same number of cavities.

Efficiency and Automation:Stack Mold can produce multi-components assemblies on one shot and one machine using the same parameters. By comprise on single face molds would require multiple machines.